Angle/Channel

With the wide range of products available at Ruwais Steel, we can deliver the products needs for your construction and manufacturing requirements.

What is angle/channel?

Angles and channels are the simplest types of formed steel components. They are the hot-rolled and low carbon steel components that are used in production of other structures. Angle bars usually have an L-shape with an angle of 90 degrees between the legs. This makes the structure stronger and add stability to whatever they are used in constructing.

They can be found in different sizes with varying thickness. Angles and channels can also be customized into specific dimensions for certain applications.

Steel channels are available in different sizes and thicknesses. The cross-section of a channel is a C with a straight back and two extensions on the top and bottom that are perpendicular to the back.

Manufacturing of angle/channel

Angles and channels are usually made in standard sizes but if required, products with customized dimensions can be provided as well.

Angle bars can be produced using several processes but the easiest of all is the roll forming. The roll forming helps to produce a product that has uniform cross sectional area.

Channels are also easy to produce, because a long metal with large width is pre-cut and placed into a pressing machine which flanges the metal sheet into the desired dimensions.

Types of angle / channel

Getting the steel products that you require does not come easier than at West Port. This is because we have in stock different types of angles and channels from which you get structures for whatever use that you require.

C Channel

C channel is made from hot-rolled steel. It is widely used and has several applications because it is light, durable and quite corrosion resistant. The C channel steel is also referred to as the U channel or mild steel channel. They are easy machine and weld together.

The corrosion resistance of the C channel makes it very useful for applications outdoors. Small amounts of copper, nickel and chromium are added to the C channel to make it resistant to rust and corrosion. Because the C channel is very light-weight, the fact that is both lightweight and corrosion resistant makes it very useful in manufacturing towers, construction equipment’s, poles, etc.

C channel are available as light channel steel which have narrower legs and weigh less than the ordinary channel steel. Channel steels are described based on the specification number which determines the size and grade of the steel.

H beam

H-beams are wide flanges beams. They are most commonly used in the construction industries as beams and columns. H-beams are very strong and this strength can sometimes make them difficult to fabricate and machine.

H-beams are wide flanges beams. They are most commonly used in the construction industries as beams and columns. H-beams are very strong and this strength can sometimes make them difficult to fabricate and machine.

Generally H-beams come in sizes ranging from 100 × 100 to 400 × 400. The specifications are written in terms of height × flange width.

| Height × Flange width | Standard cross section |

| 100 × 100 | 8 |

| 125 × 125 | 8 |

| 150 × 150 | 8 |

| 175 × 175 | 13 |

| 200 × 200 | 13 |

| 250 × 250 | 13 |

| 300 × 300 | 13 |

| 350 × 350 | 13 |

| 400 × 400 | 22 |

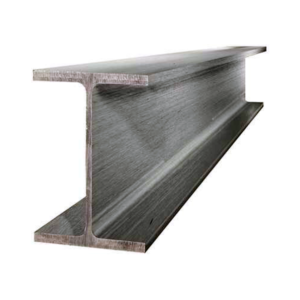

I beam

An I-beam has its flanges tapered, its flanges is also narrower than that of the H-beam. This makes it lighter in weight. The web of an I-beam most times is very thin and this makes it unable to carry much force.

I-beams are used in construction industries. Technically, they are specified as height × flange width.

Specifications

| Grade |

|

|

| flange width | 100-350 mm | |

| flange thickness | 3-14mm | |

| web width | 150-600mm | |

| web thickness | 3-12mm |

All the available at West Port are of ASTM grade. This means that we only stock products that meet international standards and can be used for several applications. We have a wide variety of products in stock that are ready for delivery wherever it is needed in the MENA region.

Quick Contact

If you have any questions or would like to book a session please contact us.

© 2024 Westport Middle East